HDPE Steel Bellows

Steel belt reinforced polyethylene (PE) spiral corrugated pipe is a kind of winding structure wall pipe with high density polyethylene (HDPE) as the matrix (inner and outer layers) and steel belt coated with adhesive resin on the surface.

Product Description

Steel Belt Reinforced Polyethylene (PE) Spiral Corrugated Pipe For Buried Drainage

Product Introduction:

Steel belt reinforced polyethylene (PE) spiral corrugated pipe is a kind of winding structure wall pipe with high density polyethylene (HDPE) as the matrix (inner and outer layers) and steel belt coated with adhesive resin on the surface. The pipe wall structure is composed of three layers: the inner layer is a continuous solid-walled PE inner pipe, and the inner pipe is wound with a ring-shaped corrugated steel belt reinforcement (formed into a "U" shape with a steel plate). The outer layer of polyethylene is compounded to form a whole spiral corrugated pipe. It is a composite pipe that organically combines the plastic-coated steel strip and polyethylene plastic in a hot-melt state.

Product Application Range:

Mainly used in municipal engineering sewage, wastewater, rainwater systems; sewage, wastewater, rainwater systems in residential quarters; drainage projects such as railways and highways. Industrial and mining wastewater systems; gravity water delivery systems for agriculture, water conservancy, and forestry irrigation.

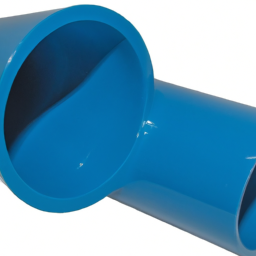

Schematic Diagram of the Pipe Structure:

Features:

◎ Large diameter and high strength: Due to the use of U-shaped steel belt composite PE material, the ring stiffness of the pipe is greatly improved without increasing the cost, and the strength is greatly improved compared with the winding pipe and the carat pipe under the same weight, which can solve heavy loads And a series of problems, the ring stiffness is kept above 8KN/m², which is lighter in weight and higher in strength than cement pipes and other plastic pipes.

◎ Reliable performance: The compounding of each layer is carried out in the molten state of plastic, which is different from the winding pipe (air wall pipe), so the layers are completely bonded and the firmness is very high.

◎ Corrosion resistance and long service life: Special pretreatment is carried out on the surface of the steel strip to increase the corrosion resistance of the steel and the adhesion between the steel and the plastic to improve the peel strength. When the plastic raw material is fully melted, it is wound and formed, and the overall structure of the pipe is firm and reliable. Due to the use of special materials and processes, both the anti-corrosion problem of the steel plate and the adhesion between the steel plate and the "material" are solved, so that the service life of the pipeline is the same as that of pure plastic pipelines, guaranteed to be more than 50 years.