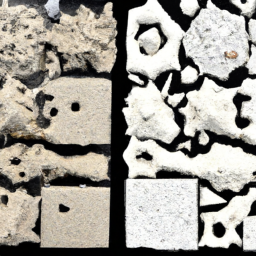

lost foam casting vs sand casting

When it comes to choosing the right casting method for your project, the age-old debate of lost foam casting vs sand casting is one that often comes up.

Product Description

If you are looking for more details, kindly visit Ruiou.

When it comes to choosing the right casting method for your project, the age-old debate of lost foam casting vs sand casting is one that often comes up. Both methods have their advantages and disadvantages, but ultimately it comes down to what will work best for your specific needs.

Lost foam casting, also known as evaporative-pattern casting, is a process that uses a foam pattern to create the final metal part. The foam pattern is coated with a refractory material and then placed in a mold. When the molten metal is poured into the mold, the foam pattern vaporizes, leaving behind a precise replica of the pattern.

One of the key benefits of lost foam casting is the ability to create complex shapes and intricate designs that may be difficult to achieve with other casting methods. This method also allows for tight tolerances and minimal finishing required, saving time and money in the long run.

On the other hand, sand casting is a more traditional method that uses a sand mold to create the final metal part. While not as precise as lost foam casting, sand casting is a versatile and cost-effective option for a wide range of applications. Sand casting is ideal for larger pieces or low volume production runs, making it a popular choice for many industries.

When deciding between lost foam casting vs sand casting, consider the specific requirements of your project. If you need a highly detailed and complex part with tight tolerances, lost foam casting may be the best option for you. However, if you are looking for a cost-effective solution for larger pieces or low volume production, sand casting may be the way to go.

No matter which method you choose, both lost foam casting and sand casting have their own unique benefits and advantages. Ultimately, the decision will come down to what will work best for your specific project needs. Remember to weigh the pros and cons of each method carefully to ensure you are making the right choice for your casting project.

For more information, please visit our website.

If you want to learn more, please visit our website Complete equipment for lost foam casting.