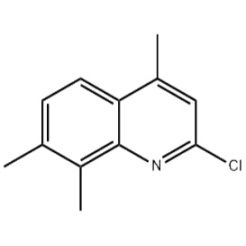

Similar to PE PX100

PX100 is a ADDPI classic and best seller ! This PE-like material is ideal for many automotive manufacturers The perfect partner for silicone: tough, impact-resistant, moderately heat-resistant, good mechanical properties and easy to process.

Product Description

1. Description

DPI-PX100 Used by casting in silicone molds for the production close to those of thermoplastics, to making sample or prototype pieces.

DPI -PX100 is a low viscosity,easy processing,can be painted,long pot-life and have good mechanical properties vacuum casting polyurethane.

2. Basic Properties

|

Item |

Value |

Remarks |

|

|

Appearance |

A Comp. |

Light yellow |

POLYOL |

|

B Comp. |

amber |

ISOCYANATE |

|

|

Color of Article |

|

Off-white |

|

|

Viscosity (mPa.s,25℃) |

A Comp. |

175 |

|

|

B Comp. |

60 |

BROOKFIELD-LVT |

|

|

mixing |

100 |

|

|

|

Density of parts before mixing at 25°C |

A Comp. |

1.02 |

|

|

B Comp. |

1.15 |

Specific Gravity Cup |

|

|

Density of cured mixing at 23°C |

|

1.06 |

Standard Hydrometer |

|

Mixing Ratio |

A:B |

100:100 |

Parts by weight |

|

Pot Life |

(25℃) |

15 Min |

Resin 200g |

|

Complete hardening time |

23℃ |

4days |

|

|

Hardness |

Shord D |

75 |

|

|

Tensile strength |

MPa |

40 |

ISO 527:1993 |

|

Elongation |

MPa |

55 |

ISO 527:2001 |

|

Flexural modulus of elasticity |

MPa |

1500 |

ISO 527:2001 |

|

Charpy impact resistance |

KJ/ m2 |

25 |

ISO 179/2D:1994 |

|

Glass Transition Temperature (Tg) |

℃ |

75 |

T.M.A Metter |

|

Linear shrinkage |

% |

2 |

Mm/m |

|

Maximal casting thickness |

mm |

5 |

|

3. Vacuum Casting Process

1). Pre-degassing

Remix POLYOL before each weighing. Degas each part before use. 2).Temperature of resin

If in the low temperature storage, the work will be A and B two liquid heating to 20 ℃ 3).Mold temperature

Pre-heated the silicone mold at 35°C- 40°C to accelerate the process. 4).Casting

Mix until a homogeneous and transparent, degas under vacuum for 5 minutes, cast in a mold pre-heated at 35°C- 40°C.

5). Curing condition Allow to cure 120 minutes at 70°C before demolding. After demolding cure 2 hours at 70°C in order

to obtain the optimal properties.

4. Precautions in handling

1). As both A and B components are sensitive to water, don't allow water get into material or don't allow moisture in the air come into prolonged contact with the material. Close container tight after use. 2) Penetration of water into A component may lead to generation of much air bubbles in the cured product. If this should happened, we recommend to heat A component to 60℃-70℃ and degas it under vacuum for about 30 minutes.

3) .B component in part or in whole may freeze when it is stored for longer period of time at temperatures below 5℃ . Frozen material can be used after melting. Warm up container to 60 ~70℃ for 1~2 hours and use the material after stirring it well.

4) .When B component is stored in a frozen state, it deteriorates more quickly on age than a liquid material. We recommend to melt it completely and store at 20~25℃ .

5. Precautions in Safety and Hygiene

1). ensure good ventilation

2). wear glove. Take care that hands or skin are not coming in direct contact with raw materials. In case of contact, wash with soap and water immediately. It may irritate hands or skin if they are left in contact with raw materials for longer period of time.

3). wear safety glasses. If raw materials get into eyes, rinse with flowing water for 15 minutes and call a doctor.

4). Install duct for vacuum pump to ensure that air is exhausted to the outside of the work shop.

6. STORAGE CONDITIONS

Shelf life is 12 months in a dry place and in the original unopened containers at a temperature between 15 and 25°. Any opened container must be tightly closed under a dry gas blanket.

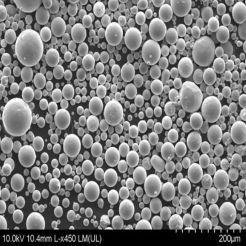

7. Delivery For

A Component: 5kg tin can.

B Component: 5kg tin can.

Email: winnie@dpipuresin.com

Mob.: +86 189 2829 5602

Tel.: +86 0769 8524 2101

WeChat: +86 189 2829 5602

Skype: +86 189 2829 5602

Whatsapp: +8618928295602

Add.: No. 12, Zhuyuan Road, Baisha Village, Humen Town, Dongguan City