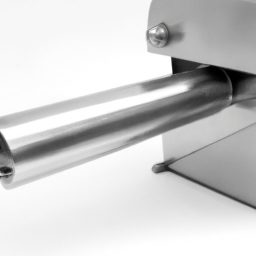

precision cnc horizontal turning

Introduction:The Precision CNC Horizontal Turning machine is designed for high-efficiency precision machining of complex components

Product Description

Product Description for Precision CNC Horizontal Turning

Introduction:The Precision CNC Horizontal Turning machine is designed for high-efficiency precision machining of complex components. With advanced computer numerical control, this machine delivers exceptional accuracy and repeatability, making it ideal for industries such as aerospace, automotive, and medical equipment manufacturing. It can handle a variety of materials, including metals, plastics, and composites, ensuring versatility for diverse applications.

Key Specifications:

- Max Turning Diameter: Up to 300mm

- Max Turning Length: 1000mm

- Spindle Speed: 0-4000 RPM

- Tool Capacity: 12-20 tools

- Power Supply: 220V/380V, 50/60Hz

- Weight: Approximately 1500 kg

Unique Features:

- High Precision: +/- 0.001mm accuracy ensures exceptional finish quality.

- Advanced CNC Technology: Seamless integration with CAD/CAM systems for enhanced operational efficiency.

- User-Friendly Interface: Intuitive touchscreen control and advanced programming capabilities for streamlined operation.

- Durable Construction: Built from high-quality alloy steel, ensuring longevity and reliability under demanding conditions.

- Smart Monitoring: Integrated AI technology for predictive maintenance and real-time performance tracking.

Material Quality:

- Types: Capable of machining a wide range of materials including stainless steel, aluminum, brass, and engineered plastics.

- Durability: Engineered to withstand high-stress machining operations with minimal wear and tear.

Dimensions:

- Size: Compact design suitable for diverse workspace environments.

- Weight: Sturdy at 1500 kg, providing stability during high-speed operations.

- Capacity: Supports various workpiece sizes up to a maximum of 300mm in diameter and 1000mm in length.

Technology:

- AI Integration: Predictive analytics capabilities to enhance machine uptime and maintenance forecasting.

- Smart Features: Automatic tool detection and compensation to minimize setup time and optimize cutting operations.

Performance:

- Efficiency: Achieves rapid cycle times with a spindle speed of up to 4000 RPM.

- Speed: Quick tool changes and adaptive machining enhance production rates.

- Capability: Efficiently processes complex geometries with tight tolerances, reducing the need for secondary operations.

Problem Solving:The Precision CNC Horizontal Turning machine addresses common manufacturing challenges by providing unparalleled accuracy and efficiency in machining operations. Its advanced technology reduces downtime and operational costs, while its durable construction translates to lower maintenance requirements. Businesses can expect improved output quality while meeting the rigorous demands of modern production environments. By investing in this machine, companies can significantly enhance their operational capabilities, streamline workflow processes, and ultimately drive profitability.

Conclusion:Upgrade your machining capabilities with the Precision CNC Horizontal Turning machine—a reliable solution that optimizes performance and precision while delivering impressive value for your investment.

Related Products:precision cnc horizontal turning, high precision double head cnc lathe solution