Why Do Graphite Electrodes Need To Be Replaced Regularly

Title: Unveiling the Key to Ensuring Optimal Performance: Understanding Graphite Electrode Replacement.

Product Description

KFCC supply professional and honest service.

Title: Unveiling the Key to Ensuring Optimal Performance: Understanding Graphite Electrode Replacement.

Subtitle: Maximizing Efficiency, Quality, and Profitability for Your Industrial Operation.

Are you tired of encountering frequent disruptions, decreased productivity, and compromised quality in your industrial processes? Look no further! We present to you the ultimate solution to all your concerns - the regular replacement of graphite electrodes. By delving into the reasons behind this necessary practice, we aim to empower you with the knowledge needed to unlock unprecedented levels of efficiency and profitability.

Unveiling the Secrets of Graphite Electrode Replacement:

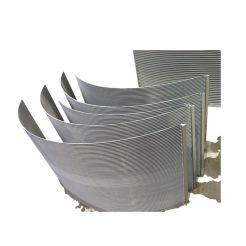

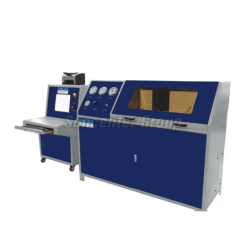

1. Consistent Performance: Graphite electrodes are indispensable components in various industries, including steelmaking, foundries, and electric arc furnaces. By replacing them regularly, you ensure an uninterrupted flow of electrical current, facilitating optimal functioning and maintaining consistent performance throughout your operations.

2. Enhanced Conductivity: Over time, graphite electrodes gradually experience wear and tear, affecting their electrical conductivity. Replacing them at the right intervals allows for the usage of electrodes with higher conductivity, translating into improved energy efficiency, reduced energy consumption, and ultimately, cost savings.

3. Preventing Process Disruptions: Frequent electrode replacement prevents the formation of cracks, fractures, and other deformations that may compromise their structural integrity. By avoiding these issues, you eliminate the risk of unplanned downtime, ensuring seamless production, and meeting customers' demands without any unforeseen interruptions.

4. Ensuring Product Quality: Graphite electrodes play a pivotal role in the manufacturing process of steel, alloys, and other materials. Their optimal condition guarantees superior product quality, including precise carbon control, reliable temperature distribution, and reduced impurities. Regular replacement safeguards against productivity losses, waste reduction, and ultimately, helps you deliver exceptional end products that meet stringent industry standards.

5. Heightened Safety: Aging graphite electrodes may pose safety hazards, such as arcing, electrical breakdowns, or even accidents caused by compromised structural integrity. By timely replacing these components, you create a safer working environment, protecting your workforce and valuable assets from potential risks, downtime, and costly repairs.

6. Sustainable Resource Management: Replacing graphite electrodes at appropriate intervals enhances the recyclability of the used electrodes and promotes sustainable resource management. By adhering to this practice, you contribute to environmental preservation and reduce your carbon footprint, aligning your business with modern eco-conscious trends.

Why Choose Regular Graphite Electrode Replacement?

✓ Maximize efficiency and productivity in your industrial processes.

✓ Optimize energy consumption, reducing operational costs.

✓ Eliminate unplanned downtime, ensuring consistent production flow.

✓ Maintain the highest standards of product quality and customer satisfaction.

✓ Safeguard workplace safety and protect valuable assets.

✓ Embrace sustainability by promoting resource recycling and eco-conscious practices.

Now is the time to take charge of your industrial operation. Remember, regular graphite electrode replacement is the key to unlocking unmatched efficiency, sustainability, and profitability. Invest in the longevity and success of your business by incorporating this fundamental practice into your maintenance strategy. Experience seamless operations, elevated product quality, and a truly satisfied customer base like never before!

Are you interested in learning more about 500mm UHP Graphite Electrode Features? Contact us today to secure an expert consultation!