induction hardening uses

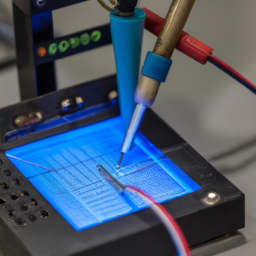

Introducing our cutting-edge induction hardening technology, designed to revolutionize the way you approach metal engineering.

Product Description

If you want to learn more, please visit our website TY-induction.

Introducing our cutting-edge induction hardening technology, designed to revolutionize the way you approach metal engineering. With our state-of-the-art equipment and expertise, we bring you an unparalleled solution that enhances the strength and durability of your metal products. Delve into the realm of advanced manufacturing and experience the transformative benefits of induction hardening.

Unleash the Power of Induction Hardening:

1. Enhanced Strength and Durability:

By subjecting metal components to our induction hardening process, we elevate their structural integrity and fortify them against wear and tear. Our technology enables precise heat treatment, resulting in increased hardness throughout the material. This ensures extended lifespan and exceptional performance under extreme conditions, giving you a competitive edge in the market.

2. Exceptional Resistance to Surface Wear:

Induction hardening creates a thin yet remarkably tough surface layer on your metal parts, offering outstanding resistance against erosion, abrasion, and other forms of surface wear. With this protective shield, your products can endure harsh environments, heavy workloads, and continuous usage, delivering unmatched reliability and longevity.

3. Precision and Consistency:

Our induction hardening process uses advanced control systems and innovative techniques to achieve precise and consistent results. Each component receives undivided attention, guaranteeing uniform hardening across the entire part, regardless of its shape or size. This ensures that every product you manufacture meets the highest quality standards, leaving no room for compromise.

4. Increased Efficiency and Cost Savings:

As induction hardening significantly improves the strength and wear resistance of metal parts, you can achieve optimal performance using lighter, more cost-effective materials. This allows you to streamline your manufacturing process, reduce material expenses, and enhance overall operational efficiency. Experience the economic advantage of using our induction hardening technology in your production line.

5. Tailored Solutions for Your Application:

We understand that different industries have unique requirements. That's why our induction hardening technology offers flexibility to meet your specific needs. Whether you're manufacturing gears, shafts, bearings, or any other metal components, our experts will customize the process to ensure exceptional results. This tailored approach optimizes your product's performance, extending its lifespan and enabling you to surpass customer expectations.

Choose Excellence in Metal Engineering:

Investing in our induction hardening technology means investing in the future of your business. With our expertise and commitment to excellence, we empower you to create superior products that redefine industry standards. Enhance your reputation, delight your customers, and gain a competitive advantage with our advanced induction hardening solutions. Join the league of success and propel your business towards new horizons of excellence.

If you are looking for more details, kindly visit our website.

Contact us to discuss your requirements of induction braze. Our experienced sales team can help you identify the options that best suit your needs.