TCT saw blade

TCT saw blade is short for tungsten carbide tipped saw blade which is used to cut steel and aluminum product is room temperature,These tips are ground on all surfaces to create tangential and radial clearance and provide the proper cutting and clearance angles on the teeth.

Product Description

TCT saw blade are made with an alloy steel body and tungsten carbide inserts brazed to the tips of the teeth. These tips are ground on all surfaces to create tangential and radial clearance and provide the proper cutting and clearance angles on the teeth. The alloy body is generally made from a wear resistant material such as a chrome vanadium steel, heat treated to 38/42 HRc . The tungsten carbide tips are capable of operating at much higher temperatures than solid HSS cold saw blades, therefore, TCT cold saw blades are usually run at much higher surface speeds. This allows carbide-tipped blades to cut at faster rates and still maintain an acceptable chip load per tooth. The tungsten carbide inserts are extremely hard (98 HRc) and capable of very long wear life. However, they are less resistant to shock than solid HSS cold saw blades. Any vibration during the cutting process may severely damage the teeth. Fortunately, the tungsten carbide tipped saw blade tips can be replaced. As long as the saw blade body is not damaged, the customer can replace the damaged carbide tips and continue to use it, thus reducing the use cost of the saw blade.

Application

1.Carbide tip for seamless steel pipe

It is mainly used for scaling-off cutting various kinds of tubes in the cooled and straightened condition after hot rolling by the seamless steel tube factory. The saw blade can cut several steel tubes on a row at a time.

|

Diameter (mm) |

Kerf (mm) |

Thickness (mm) |

Bore hole (mm) |

Pin hole (mm) |

PCD (mm) |

Teeth number |

|

540 |

6.5 |

5.0 |

60 |

22 |

125 |

60 |

|

830 |

7.0 |

5.5 |

100 |

27 |

160 |

70 |

|

965 |

8.0 |

6.5 |

100 |

30 |

200 |

50/60 |

|

1020 |

8.0 |

6.5 |

100 |

30 |

200 |

60/80 |

|

1250 |

8.5 |

7.0 |

100 |

31 |

250 |

70/80 |

Advantages

High line speed

High blade life

Burr free cut

2.Carbide tip for steel bar

It is mainly used for cutting round steel bar in the cold condition; the cutting diameter can reach 450mm. It also can be used for cutting the steel rails of normal temperature and used with various kinds of cutting machines.

|

Diameter (mm) |

Kerf (mm) |

Thickness (mm) |

Bore hole (mm) |

Pin hole (mm) |

PCD (mm) |

Teeth number |

|

830 |

6.5 |

5.0 |

100 |

30 |

200 |

80/100 |

|

1020 |

7.0 |

5.5 |

100 |

30 |

200 |

100/120 |

|

1250 |

7.0 |

5.5 |

100 |

30 |

250 |

150/160 |

|

1400 |

8.0 |

6.5 |

100 |

30 |

300 |

160/180 |

|

1650 |

10 |

8.5 |

100 |

42 |

420 |

160/200 |

|

1800 |

10.5 |

9.0 |

100 |

42 |

420 |

180/240 |

Advantages

High blade life on solid cutting

Low noise

Smooth surface

Low cost per cut

3.Carbide tip for Aluminum

It is mainly used for cutting aluminum bar materials with different sections for Aluminum processing factory. The cutting diameter can reach 700mm, and the thickness of the flat aluminum bar can reach 700mm.

|

Diameter (mm) |

Kerf (mm) |

Thickness (mm) |

Bore hole (mm) |

Pin hole (mm) |

PCD (mm) |

Teeth number |

|

1000 |

8.0 |

6.5 |

100 |

18 |

200 |

120/160 |

|

1200 |

8.5 |

6.5 |

100 |

22 |

250 |

80/100 |

|

1250 |

8.0 |

6.5 |

100 |

22 |

250 |

180/200 |

|

1400 |

8.5 |

7.0 |

100 |

22 |

250 |

200/220 |

|

1560 |

11 |

9.5 |

100 |

30 |

250 |

81/240 |

|

1600 |

10.5 |

8.5 |

200 |

25 |

300 |

72/80 |

|

1800 |

10.5 |

9 |

150 |

30 |

300 |

230/250 |

|

2000 |

15 |

11 |

240 |

30 |

350 |

70/100 |

|

2200 |

15.5 |

11.5 |

240 |

30 |

350 |

90/120 |

Coated Carbide Tipped for high carbon steel alloys, reduces heat-wear and distortion

Advantages

Lower cost per cut

Wide variety of tooth counts to accommodate your part

Stiff and extremely flat plates ensure distortion-free accurate cuts

Increased productivity (less downtime)

Excellent cut quality

TCT saw blade saw body material

It is mainly used Chrome steel 75Cr1.

TCT saw blade diameter

The saw blade diameter is from 500 to 2200mm

Advanced production equipment and mature production process

The quality control of tungsten carbide tipped saw blade requires not only high-quality steel plate and carbide tips, but also precise processing machine. Our company is equipped with a fully automatic brazing machine and a teeth profile grinding machine imported from Germany.

Quality control

The main technical parameters of TCT saw blades are tension, run out, dynamic balance (above 1200 large diameter) and tooth shape design.

We will select the suitable tooth shape at the beginning of the order according to the material and specifications of the object to be cut. And strictly control the segmental quality inspection of each process, and do the final quality control inspection before in stock. Ensure that the manufactured products meet the technical requirements.

However, since the saw blade is a matching accessory of the saw machine, because the actual cutting and using conditions of the saw machine are different, the parameters of the saw blade may be inappropriate at first, and the parameters need to be changed according to the actual situation of the saw machine. We also respond quickly, determine the direction of the next improvement based on the actual situation. Adjust the saw blade to meet the customer's saw machine conditions.

Main re-conditioning equipment

Grinding machine for teeth seat ground

Brazing machine for carbide teeth brazing

Grinding machine for carbide teeth front and back angle ground

Grinding machine for carbide teeth side angle ground

Tension machine

Passivation machine

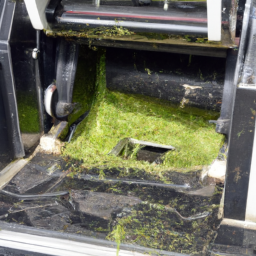

Cutting effect

Email: yfmachinetech@hotmail.com

Mob.: +86 153 2425 0935

Tel.: +86 315 287 3612

Fax: +86 315 287 3612

WeChat: +86 153 2425 0935

Skype: YFMACHINE

Whatsapp: +8615324250935

Add.: Mengzhuang Village, Xige Town, Tangshan City, Hebei Province, China.