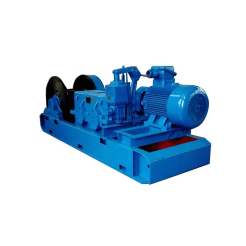

PEX Series Jaw Crusher

PEX series jaw crusher is developed and applied widely in mines, quarries, road construction, building material, highway, railway, water conservancy and other industrial.

Product Description

1. Brief introduction

PEX series jaw crusher is developed and applied widely in mines, quarries, road construction, building material, highway, railway, water conservancy and other industrial. The product specification is complete, the feed size from 150-1500 mm, PE/PEX-type jaw crusher crushing materials of compressive strength of up to 300Mpa, it is a complete set of broken lines in the first choice of primary crushing equipment.

2. Jaw Crusher Advantage and Feature

a. High efficiency with uniform particle size.

b. Simple structure, and easy to operate, reduce the operation cost.

c. Crushing chamber is deep and has no dead space, which helps improve the feeding capacity and productivity.

d. Adjustment device of gasket type discharging end is reliable and convenient to use.

e. The discharging end has wide adjusting range which can increase the flexibility of our equipment.

f. Lubrication system is safe and reliable.

g. Over loading protection.

h. Accessories are convenient to replace, and little maintenance is needed.

3. Technical Data

|

Technical Data |

||||||

|

Model |

Max. Feeding Size (mm) |

Discharge Opening (mm) |

Capacity (tph) |

Motor (kW) |

Weight (t) |

Overall Dimension (mm) |

|

PEX150x750 |

120 |

18-48 |

8-25 |

15 |

3.5 |

1380x1658x1025 |

|

PEX250x750 |

210 |

25-60 |

13-35 |

30 |

4.96 |

1545x1667x1330 |

|

PEX250x1000 |

210 |

25-60 |

16-52 |

30-37 |

6.5 |

1530x1992x1380 |

|

PEX250x1200 |

210 |

25-60 |

20-61 |

37-45 |

8.52 |

1900x2192x1430 |

|

PEX300x1300 |

250 |

20-90 |

25-95 |

55-75 |

12.6 |

1750x2320x1724 |

|

PEX350x1200 |

300 |

70-140 |

25-120 |

75 |

12.35 |

2162x2220x1723 |

Details about primary crushing, medium and fine crushing

1. Crushing: feed particle size is 300~900mm, the grain size is 100~550mm;

2. Pieces: feed particle size is 100~350mm, the grain size is 20~100mm;

3. Fine: feed particle size is 50~100mm, the grain size is 5~15mm.

4. Jaw Crusher Working Principle

This jaw crusher uses motor as its power, through the motor's wheels, the eccentric shaft is driven by the triangle belt and slot wheel to make the movable jaw plate move by a regulated track. Therefore, the materials in the crushing cavity composed of fixed jaw plate, movable jaw plate and side-lee board can be crushed and discharged through the discharging opening.

5. Successful Project

Email: newregmachinery@gmail.com

Email: elvis@newregmachinery.com

Mob.: +86 18242849166

WeChat: +86 18242849166

Whatsapp: +6580675679

Add.: 2 KALLANG AVENUE #03-02 CT HUB SINGAPORE (339407)