Wind Turbine Forgings

Wind turbine ring forging is an important part of the wind turbine system. We are a certified supplier of Vestas, Siemens Gamesa and GE, and have sold our products globally.

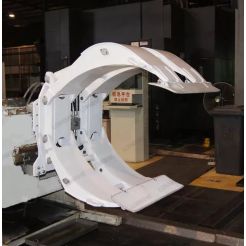

Product Description

wind turbine forgings

We have rich manufacturing experiences in this industry.

Wind turbine ring forging is an important part of the wind turbine system.

We can provide products such as tower connecting flanges, the bottom flanges, the transition piece (TP flanges), MP flanges(monopiles), jackets flange, tower doorframes, forgings for yaw and pitch systems; forgings of gear boxes, wind power generator stator rings and rotor rings and offshore platform forgings and other products.

We are a certified supplier of Vestas, Siemens Gamesa and GE, and have sold our products globally.

With respect to large megawatt wind turbines, we have successively provided customers with multiple sets of 10MW+ tower flanges such as DEC 10MW, Mingyang 10MW, CSSC 10MW, GE12MW, Siemens Gamesa 11/14MW, Vestas 10MW and so on. And we also have participated in compiling the "Ring Type Forgings of Wind Turbine Generator System" standards developed by National Energy Administration, and the "Precision Forming Technology and Equipment for Wind Turbine Ring Forgings" is listed in China's Torch Plan.

Technical Data

|

Material |

Carbon steel and alloy steel |

|

Size Range |

Diameter ≤ 16m |

|

Piece Weight Range |

Piece weight ≤ 200 tons |

|

Heat Treatment |

Normalizing and tempering |

|

Testing |

Low-temperature impact test, high-temperature tensile test, metallography detection, hardness test, chemical element analysis, non-destructive testing. |

|

Equipment Capacity |

6 forging and pressing production lines consisting of 13,500-ton oil press-16 m rolling mills and 2,000 tons oil press-3 m ring rolling, with corresponding heat treatment and machining equipment. |

|

Production Capacity |

200,000 tons/year |

Wind Power

On january 4,2023, the barrel flange of Goldwind 16MW prototype wind turbine was successfully dispatched. The products will be installed on the GWH252-16MW offshore wind turbine, which is developed jointly by China Three Gorges Corporation and Goldwind with fully independent intelllectual property rights.

The impeller diameter of the unit reaches 252 meters, and the impeller sweeps the wind are a of about 50000 square meters, which is equivalent to the area of 7 standard soccer fields. A single unit can output more than 66 million kilowatt hours of clean electricity per year, which can satisfy the normal electricity consumption of 36000 families with three mouth for one year, reduce coal consumption by 22000 tons, and reduce carbon dioxide emission by 54,000tons with significant energy-saving and emission reduction effects.

We set up a special technical quality team to demonstrate and follow up on key processes to ensure the stability and reliability of the product quality. Finally, in less than half a month, the delivery of the supporting flange for the unit was completed.

Email: crusherandparts@gmail.com

Mob.: +86 178 0247 4096

Tel.: +86 024 2324 6789

Fax: +86 024 2324 6789

WeChat: +86 178 0247 4096

Whatsapp: +8617802474096

Add.: Room 504-6, No. 858-20, Shangshengou Village, Hunnan District, Shenyang City, Liaoning Province