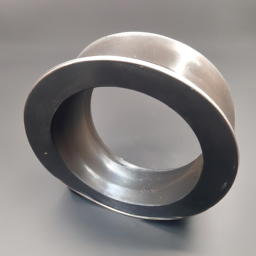

Flexible Graphite Wire

Flexible Graphite Wire

Product Description

Flexible Graphite Wire is manufactured from mineral graphite, expanded graphite bursts into the 800℃-1100℃ expansion furnace by high pressure, due to the absorption of the compound in the layer lattice decomposition, the volume of arbitrary expansion 160 times to 280 times, into a very low density of worm-like, adding cement and different natural fibers

Flexible graphite wire is used to expand graphite through high pressure instantaneously into the high temperature 800℃-1100℃ expansion furnace, due to the absorption of the compound in the layer lattice decomposition, the volume of arbitrary expansion 160 times to 280 times than before, into a very low density of worm-like, adding adhesive and different natural fibers, such as: Cotton yarn、glass fiber and carbonized fibre as well as others reinforcing materials form into strips. After the compounding and cutting processes of the composite machine in addition to other process,it is sent to spinning machine to textile.

Product characteristics

In order to adapt to different working conditions, metal materials such as nickel alloy wire, stainless steel wire and copper wire can be inserted, and various types of reinforced flexible graphite wires can be made through specific processes, which are used to weave flexible graphite coils with different effects in the sealing industry and various specifications of graphite grounding bodies in the power industry.

Customization interval

Conventional: 2g/m; 3g/m; 5g/m

2-12g/m can be customized, and different reinforcement materials can be added as required.

Flexible graphite wire parameters

| Product Parameter | |

| Specifications and models | 2g/m,3g/m,5g/m, 2-12g/m Can be customized |

| Wire diameter | 2mm,3mm,5mm |

| Carbon content | ≥99% |

| Resistance ionization | ≤3.75×10Ω•m |

| Sulphur content | ≤1000ppm,no sulphur: s50ppm low sulphur:≤700ppm |

| Chlorinity | ≤50ppm |

| Density | 0.9-1.3g/cm³ |

| Strength of extension | ≥10MPa |

| Firing loss rate | ≤12%(450°C,burning for 3 hours) |

| Thread twist | s230°/m |