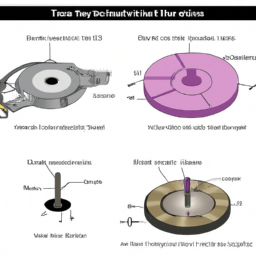

Cooling Fans

Product origin: guangdong 15 years OEM and ODM one-stop service, manufacturing all kinds of metal parts, ranging from precision metal parts to large sheet metal stamping parts, according to customer order quantity, we provide the most cost-effective way for your project, we Can use laser cutting, continuous progressive die automatic production.

Product Description

Precision Stamping Industries: Meeting Engineering and Processing Challenges

Welcome to , a reputable enterprise specializing in high-speed stamping and insulation coating for motor core components. With our expertise and commitment to quality, we have become a trusted name in the industry since 2012. Our ISO9001 and IATF16949 certifications validate our dedication to excellence.

With a wide range of press capacities, from 25 tons to 300 tons, we can provide stamped parts of various sizes. Our mission is to assist our customers in overcoming the most demanding engineering and processing challenges. If you are interested in our Cooling Fans, feel free to !

Precision Stamping Industries: Meeting Diverse Needs

Precision stamping is a versatile manufacturing process that finds applications across multiple industries. Let's dive into some of the key industries that benefit from precision stamping:

1. Automotive Industry

The automotive industry relies heavily on precision stamping for the production of various components. From engine parts and transmission components to brackets and connectors, precision stamping ensures the high-quality and reliable performance of these critical components. The ability to produce customized stamped parts based on specific design requirements makes precision stamping indispensable in the automotive sector.

2. Electronics Industry

The electronics industry demands precise and intricate components to power our modern devices. Precision stamping plays a crucial role in manufacturing connectors, terminals, and other electronic components. The high accuracy and repeatability offered by precision stamping ensure the proper functioning and reliability of these intricate electrical parts.

3. Aerospace and Defense Industry

The aerospace and defense sectors have stringent requirements for precision components. From aircraft engine parts to missile guidance systems, precision stamping guarantees the manufacturing of complex and high-precision components that meet the industry's strict standards. The ability to produce lightweight yet robust parts makes precision stamping an essential process in these industries.

4. Medical Industry

In the medical industry, precision is of utmost importance. Precision stamping enables the production of medical components such as surgical instruments, implants, and diagnostic equipment. The ability to manufacture parts with tight tolerances ensures the precise performance and compatibility of these critical medical devices.

5. Energy and Renewable Industry

The energy and renewable industry relies on precision stamping for the production of components used in power generation and transmission. From electrical connectors and terminals to solar panel frames and wind turbine parts, precision stamping ensures the efficient and reliable operation of these energy systems.

6. Consumer Goods Industry

Precision stamping also finds applications in the consumer goods industry. The manufacturing of products such as kitchen appliances, hardware, and electronics requires precise and durable components. Precision stamping offers a cost-effective solution for producing high-quality components at scale, meeting the demands of consumer goods manufacturers.

Advantages of Precision Stamping Industries

Precision stamping industries offer numerous advantages for manufacturers across different sectors. Here are some key benefits:

1. Cost-Effective Production

Precision stamping enables cost-effective production by minimizing material waste and reducing labor costs. The automated nature of the process ensures high-speed and efficient production, resulting in reduced overall manufacturing costs.

2. Customization and Design Flexibility

Precision stamping allows for customization and design flexibility. Manufacturers can produce components with intricate shapes, complex geometries, and unique features. The ability to tailor components to specific design requirements opens up new possibilities for innovative product development.

3. High-Quality and Consistency

Precision stamping ensures high-quality and consistent results. The process offers tight tolerances and exceptional accuracy, resulting in components that meet the strictest quality standards. Consistent production eliminates variations and ensures the reliability of the final products.

4. Rapid Response and Short Lead Times

Precision stamping industries prioritize rapid response and short lead times. The automated nature of precision stamping enables fast production, allowing manufacturers to meet tight deadlines and respond quickly to market demands.

5. Enhanced Productivity and Efficiency

Precision stamping improves overall productivity and efficiency in manufacturing operations. The high-speed production process reduces cycle times, increases output, and optimizes resource utilization. Manufacturers can achieve higher volumes of production while maintaining consistent quality.

6. Streamlined Assembly and Integration

Precision stamping enables the production of components that are designed for streamlined assembly and integration. The precise dimensions and consistent quality of stamped parts simplify the manufacturing process, resulting in smoother assembly and reduced production time.

Specification

| Describe | fan blade |

| Types Of | precision Stamping |

| Application | DC |

| Processing | stamping |

| Material | SPCC |

| Weight Range | 0.5-100Kg |

| Design Support | AutoCAD, Solidworks, PDF |

| Quality Control | Materials, Dimensions, Properties, Internal Defects, Balance Tests |

| Standard | ASTM, DIN, JIS, ISO, GB standard |

Main Application: apply to Motors

Advantage

1. Specialized in manufacturing iron cores for 15 years, and exporting related components for more than 10 years

2. Obtained ISO9001, IATF16949 and other certifications

3. Short delivery time

4. Competitive price

5, Equipped with automatic powder spraying line

6. Welcome to customize orders

Our service

1. Have a strong R&D team

2. Quickly respond to your inquiries and feedback

3, good quality, strict quality control

4. Professional after-sales team

Welcome to choose our products!

Precision stamping industries play a vital role in meeting the engineering and processing challenges of various sectors. With its cost-effective production, customization capabilities, and consistent quality, precision stamping offers manufacturers a competitive edge in their respective industries.

At , we are committed to providing top-quality precision-stamped components tailored to your specific requirements. Our expertise, reliable service, and dedication to customer satisfaction make us your trusted partner for all your precision stamping needs.