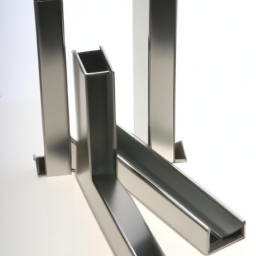

Deep Drawn Covers

Product origin: guangdong 15 years OEM and ODM one-stop service, manufacturing all kinds of metal parts, ranging from precision metal parts to large sheet metal stamping parts, according to customer order quantity, we provide the most cost-effective way for your project, we Can use laser cutting, continuous progressive die automatic production.

Product Description

High-Quality Stamped Cover Products for All Your Needs

Deep Drawn Covers

Welcome to our comprehensive guide on stamped cover products, where we provide you with detailed information about the benefits, applications, and top-quality options available in the market. At CHME, we take immense pride in offering the finest range of stamped covers that are designed to meet your specific requirements. if you are interested in our Progressive Stamping, please contact us as soon as possible.

Specification

| Describe | cover |

| Types Of | Progressive Stamping, Deep Drawn Components |

| Application | sensor |

| Processing | stamping |

| Material | SPCC |

| Weight Range | 0.5-100Kg |

| Design Support | AutoCAD, Solidworks, PDF |

| Quality Control | Materials, Dimensions, Properties, Internal Defects, Balance Tests |

| Standard | ASTM, DIN, JIS, ISO, GB standard |

Main Application: apply to Sensor

Advantages of Stamped Covers

1. Durability and Strength

Stamped covers are crafted from high-quality materials that exhibit excellent strength and durability. They can withstand demanding conditions, including extreme temperatures, heavy impact, and chemical exposure, without compromising their structural integrity. This durability ensures long-lasting protection for the components they cover.

2. Customizability

One of the significant advantages of stamped covers is their ability to be customized according to specific project requirements. Manufacturers offer a wide array of designs, sizes, and materials to choose from, allowing you to find the perfect fit for your application. This customization ensures optimal functionality and aesthetic appeal.

3. Cost-Effectiveness

Stamped covers provide a cost-effective solution for protecting valuable components and equipment. By preventing damage, they help reduce maintenance and replacement costs in the long run. Additionally, their long lifespan ensures extended use, making them a wise investment for various industries.

Understanding Stamped Covers

Stamped covers are versatile components used in a wide range of industries and applications. These covers are manufactured using advanced techniques, such as stamping, which involves the shaping or cutting of materials to create intricate patterns and designs. Stamped covers offer a blend of durability, functionality, and aesthetic appeal, making them an ideal choice for various projects.

Applications of Stamped Covers

Industrial Machinery

Stamped covers find extensive use in the industrial sector, especially in machinery and equipment. They serve as protective shields, preventing contaminants from entering critical components and ensuring smooth operation. These covers can withstand harsh conditions and provide an added layer of safety, enhancing the overall efficiency and longevity of machinery.

Automotive Industry

In the automotive industry, stamped covers play a crucial role in protecting vital components like engines, transmissions, and electrical systems. They provide a barrier against dirt, moisture, and other external elements, maintaining the optimal performance of automotive systems. Stamped covers also contribute to the aesthetic appeal of vehicles, enhancing their overall visual appeal.

Electronics and Appliances

Stamped covers are widely used in the electronics and appliance manufacturing industry. They offer protection to delicate circuit boards, connectors, and other sensitive components from environmental factors like dust, moisture, and impact. By safeguarding these elements, stamped covers ensure the reliable performance and longevity of electronic devices and appliances.

Architecture and Design

In architecture and design, stamped covers are employed for both functional and decorative purposes. These covers add an artistic touch to structures, enhancing their visual appeal. Moreover, they serve as protective barriers, preventing damage to critical components and offering longevity to architectural projects.

Why should you choose us?

1. Specialization and Expertise: Delivering Quality for Over 15 Years

Our company takes pride in its 15 years of dedicated experience in manufacturing iron cores. Throughout the years, we have continuously honed our skills and refined our processes to ensure the production of high-quality products. Our commitment to excellence has earned us a stellar reputation among our clients, who rely on us for consistent and reliable performance. By choosing our specialized services, you can be confident in the quality and durability of the iron cores and related components you receive.

2. Certifications: Guaranteeing Quality and Compliance

We understand the importance of adhering to stringent quality standards and industry regulations. That is why we have obtained prestigious certifications such as ISO9001 and IATF16949. These certifications validate our commitment to maintaining exceptional quality management systems and adhering to best practices in the industry. By partnering with us, you can rest assured that our products meet the highest standards of quality, reliability, and durability.

3. Short Delivery Time: Ensuring Timely Solutions

Time is of the essence in today's fast-paced business environment. We recognize the significance of prompt delivery to meet your project deadlines. Our streamlined manufacturing processes and efficient supply chain management allow us to offer short delivery times without compromising on quality. Whether you have urgent requirements or need consistent and timely deliveries, our commitment to punctuality will ensure that your projects stay on track.

4. Competitive Pricing: Enhancing Your Cost Efficiency

In addition to delivering top-notch quality and timely solutions, we understand the importance of cost efficiency for businesses. We strive to offer competitive prices without compromising on the quality of our products. Through strategic sourcing, efficient production methods, and economies of scale, we can provide you with cost-effective solutions. Partnering with us means maximizing your budget and optimizing your return on investment.

5. Cutting-Edge Technology: Equipped for Excellence

To ensure that we consistently deliver superior products, we have invested in state-of-the-art technology. Our facility boasts an automatic powder spraying line, which allows for precise and efficient application of coatings to our iron cores. This advanced technology enhances the performance and longevity of our products, giving you a competitive advantage in your industry. By utilizing cutting-edge equipment, we guarantee products that meet your specifications and exceed your expectations.

6. Customization: Tailoring Solutions to Your Needs

At our company, we believe in the power of customization. We understand that every business has unique requirements and specifications. That is why we welcome custom orders, allowing you to tailor our products to your specific needs. Our experienced team will work closely with you to understand your project requirements and deliver personalized solutions that meet your exact expectations. By choosing our customization services, you can differentiate your products in the market and gain a competitive edge.

Partner with Us for Unrivaled Quality and Service

When it comes to iron cores and related components, choosing the right supplier is crucial for the success of your business. With our specialized expertise, industry-leading certifications, short delivery times, competitive pricing, cutting-edge technology, and commitment to customization, we are the ideal partner to meet your needs. Experience the advantage of working with a trusted supplier that prioritizes quality, reliability, and customer satisfaction. Contact us today and unlock the potential for excellence in your projects.

Our service

1. Have a strong R&D team

2. Quickly respond to your inquiries and feedback

3, good quality, strict quality control

4. Professional after-sales team

Enhance Efficiency and Reliability with CHME Components Co., Ltd.'s Deep Drawn Covers

As an esteemed enterprise specializing in high-speed stamping and insulation coating for motor cores, CHME Components Co., Ltd. is dedicated to providing top-notch solutions to the automotive supporting industry. With a strong focus on quality, innovation, and customer satisfaction, our company has garnered a reputation for excellence. In this article, we will delve into the advantages of our deep drawn covers and explain how they can optimize your operations and elevate your products to new heights.

1. Unmatched Expertise and Certification: Ensuring Superior Quality

With over a decade of experience in the automobile supporting industry, CHME Components Co., Ltd. possesses the necessary expertise and know-how to deliver exceptional deep drawn covers. We have successfully obtained ISO9001 and IATF16949 certifications, which serve as testaments to our commitment to upholding rigorous quality standards. By choosing our deep drawn covers, you can be confident in the reliability, durability, and precision of our products.

2. Versatility in Size and Application: Tailored to Your Needs

Understanding the unique requirements of our clients, we offer deep drawn covers in a range of sizes, catering to different press capacities from 25 tons to 300 tons. Whether you require smaller components or larger covers, we have the capabilities to meet your specific needs. Our team of skilled professionals excels in precision engineering, ensuring that every deep drawn cover matches your exact specifications and dimensions.

3. Resolving Complex Engineering Challenges: Your Reliable Partner

At CHME Components Co., Ltd., we thrive on tackling the toughest engineering and processing challenges. Our deep drawn covers are meticulously designed to overcome complexities and provide efficient solutions. From intricate geometries to demanding tolerances, our deep drawn covers exhibit excellent performance, guaranteeing seamless integration into your motor cores. With us as your partner, you can overcome engineering hurdles with confidence.

4. Customization for Unique Demands: Unleash Your Potential

We understand that each project may require unique features and dimensions. With our deep drawn covers, customization is at the forefront. By providing us with your drawings and specifications, we will work closely with you to deliver tailor-made solutions that perfectly align with your requirements. Whether you need specific coatings, insulation options, or additional features, our dedicated team will accommodate your needs, empowering you to bring your vision to life.

5. Cost-Effective Solutions: Maximizing Efficiency

CHME Components Co., Ltd. values your budget and strives to provide cost-effective solutions. Our deep drawn covers are not only competitively priced but also help save costs in the long run. By leveraging our expertise in high-speed stamping and insulation coating, we optimize the production process, reducing material waste and enhancing overall efficiency. With our deep drawn covers, you can achieve superior performance without compromising on your bottom line.

6. Responsive Customer Service: Partnering for Success

We take pride in our commitment to providing exceptional customer service. Our team is highly responsive and dedicated to addressing your inquiries and concerns promptly. We understand the importance of timely communication and aim to establish long-term partnerships built on trust and reliability. From initial consultation to after-sales support, we are here to ensure your experience with our deep drawn covers exceeds your expectations.

Elevate Your Motor Cores with CHME Components Co., Ltd.'s Deep Drawn Covers

When it comes to optimizing your motor cores, CHME Components Co., Ltd. is your trusted partner. With our expertise, industry certifications, versatility, and commitment to customization, we deliver deep drawn covers that enhance efficiency, reliability, and performance.

Our cost-effective solutions and responsive customer service further underscore our dedication to your success. Contact us today to explore the full potential of our deep drawn covers and experience the difference they can make in your operations.