Frame

Product origin: guangdong 15 years OEM and ODM one-stop service, manufacturing all kinds of metal parts, ranging from precision metal parts to large sheet metal stamping parts, according to customer order quantity, we provide the most cost-effective way for your project, we Can use laser cutting, continuous progressive die automatic production.

Product Description

Progressive Stamping

Welcome to CHME Components Co., Ltd., an enterprise specializing in the high-speed stamping and insulation coating business of motor cores. Our company has been a trusted name in the industry since 2012 when we entered the automobile supporting industry. We take pride in our ISO9001 and IATF16949 certification, which ensures our commitment to quality and customer satisfaction.

With our complete molds, reliable quality, rapid response, and thoughtful service, we strive to meet all your engineering and processing needs. Please contact us for product catalog and quotation!

Progressive Stamping: Revolutionizing the Manufacturing Industry

Progressive stamping is a cutting-edge technique that has revolutionized the manufacturing industry. It involves a series of automated presses and dies that gradually form a metal part with multiple complex features. This method allows for high-speed production of precise and intricate components. Let's delve deeper into the advantages of progressive stamping:

1. Efficient Production Process

Progressive stamping enables a streamlined and efficient production process. With our presses ranging from 25 tons to 300 tons, we can accommodate various sizes of stamped parts. The progressive nature of this technique eliminates the need for multiple operations and reduces production time significantly. By automating the process, we ensure consistent quality and minimize the margin for error.

2. Cost-Effective Solution

Progressive stamping offers a cost-effective solution for manufacturing metal components. The automated process increases productivity while reducing labor costs. Additionally, the ability to produce custom products saves on tooling expenses. At CHME Components, we prioritize affordability without compromising on the quality of our stamped parts.

3. Precision and Accuracy

With progressive stamping, we can achieve exceptional precision and accuracy in producing motor core components. The process allows for tight tolerances, ensuring that each part meets the exact specifications and requirements. Our experienced team and state-of-the-art equipment guarantee that your components are manufactured to the highest standards.

4. Flexibility in Design

Progressive stamping provides immense flexibility in design. Whether it's intricate shapes, complex geometries, or unique features, we can create customized stamped parts tailored to your specific needs. Our engineers work closely with you to understand your design requirements and translate them into reality.

5. Enhanced Productivity

By adopting progressive stamping, manufacturers can significantly increase their productivity. The automated nature of the process allows for high-speed production, reducing cycle times and increasing output. This increased productivity ultimately translates into shorter lead times, enabling you to meet tight deadlines and fulfill customer demands efficiently.

6. Quality Assurance

At CHME Components Co., Ltd., quality is our utmost priority. We adhere to rigorous quality control measures throughout the progressive stamping process. Our ISO9001 and IATF16949 certification further attest to our commitment to delivering products of exceptional quality. By partnering with us, you can be confident that you will receive reliable and durable stamped parts.

Specification

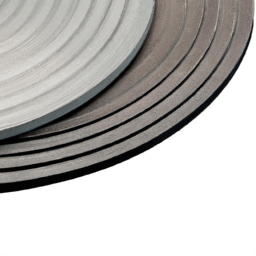

| Describe | Custom stamped stator and rotor cores |

| Types Of | Stator and rotor Core |

| Application | Oxygen pump |

| Processing | stamping |

| Material | Silicon steel |

| Weight Range | 0.5-100Kg |

| Design Support | AutoCAD, Solidworks, PDF |

| Quality Control | Materials, Dimensions, Properties, Internal Defects, Balance Tests |

| Standard | ASTM, DIN, JIS, ISO, GB standard |

Main Application

Apply to Gear box

Advantage

1. Specialized in manufacturing iron cores for 15 years, and exporting related components for more than 10 years

2. Obtained ISO9001, IATF16949 and other certifications

3. Short delivery time

4. Competitive price

5, Equipped with automatic powder spraying line

6. Welcome to customize orders

Our service

1. Have a strong R&D team

2. Quickly respond to your inquiries and feedback

3, good quality, strict quality control

4. Professional after-sales team