Stators and Rotors for DC Motors

Product origin: guangdong 15 years OEM and ODM one-stop service, manufacturing all kinds of metal parts, ranging from precision metal parts to large sheet metal stamping parts, according to customer order quantity, we provide the most cost-effective way for your project, we Can use laser cutting, continuous progressive die automatic production.

Product Description

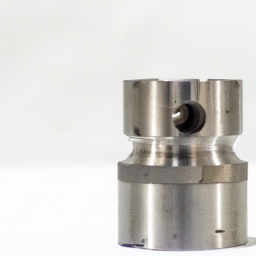

Stator And Rotor in DC Motor

The stator and rotor are two essential components of a DC motor that work together to produce mechanical motion. The stator is the stationary part of the motor that contains the coils of wire, while the rotor is the rotating part that contains the permanent magnets.

The stator is made up of a metal frame and a series of coils wound around it. These coils are usually made of copper wire and are arranged in a specific pattern to create a magnetic field when an electric current is passed through them. The stator is responsible for creating a stationary magnetic field that interacts with the rotating magnetic field produced by the rotor.

The rotor, on the other hand, is made up of a shaft, a commutator, and permanent magnets. The permanent magnets are arranged in a specific pattern around the rotor and produce a rotating magnetic field when an electric current is passed through the coils in the stator. The commutator is a device that allows the electric current to flow through the coils in the stator in a specific sequence, which creates the rotational motion of the rotor.

When the stator and rotor work together, they produce a powerful and efficient mechanical motion that can be used for a variety of applications. DC motors are commonly used in a range of industries, including automotive, robotics, and aerospace, due to their high reliability and efficiency.

In summary, the stator and rotor are the two key components of a DC motor that work together to produce mechanical motion. The stator creates a stationary magnetic field, while the rotor produces a rotating magnetic field. Together, they create a powerful and efficient motion that is widely used in a variety of applications.

Specification

| Describe | Custom stamped stator and rotor cores |

| Types Of | Stator and rotor Core |

| Application | Oxygen pump |

| Processing | stamping |

| Material | Silicon steel |

| Weight Range | 0.5-100Kg |

| Design Support | AutoCAD, Solidworks, PDF |

| Quality Control | Materials, Dimensions, Properties, Internal Defects, Balance Tests |

| Standard | ASTM, DIN, JIS, ISO, GB standard |

Application

Main Application: apply to aerators

DC motors that use a stator and rotor have many applications across various industries. Some of the most common applications include:

1. Automotive: DC motors are used in many automotive applications, including power windows, power seats, windshield wipers, and electric steering.

2. Robotics: DC motors are used in robotics for their high efficiency, compact size, and precise control.

3. Aerospace: DC motors are used in aerospace applications for their high power-to-weight ratio and reliability, including in aircraft actuators and electric propulsion systems.

4. Industrial automation: DC motors are used in industrial automation for their high torque and ability to operate at a wide range of speeds, including in conveyors, machine tools, and assembly lines.

5. Medical devices: DC motors are used in medical devices for their precise control and compact size, including in surgical instruments and pumps.

6. Consumer electronics: DC motors are used in many consumer electronics, including cameras, toys, and appliances.

Overall, the stator and rotor design of DC motors makes them a versatile option for a wide range of applications across various industries.

Advantages of Stator And Rotor in DC Motor

Some of the advantages of using a stator and rotor in a DC motor include:

1. High efficiency: DC motors are highly efficient, meaning that they convert a large amount of electrical energy into mechanical energy. This makes them ideal for applications where energy conservation is important.

2. High torque: DC motors are capable of producing high torque, which is important for applications where a lot of power is needed.

3. Simple design: The stator and rotor design of DC motors is relatively simple, making them easy to manufacture and maintain.

4. Wide range of speeds: DC motors can operate at a wide range of speeds, making them suitable for a variety of applications.

5. Long lifespan: DC motors have a long lifespan and are highly reliable, making them a popular choice for many industrial and commercial applications.

Overall, the use of a stator and rotor in a DC motor offers many advantages over other types of motors, making them a popular choice for a wide range of applications.

Our Advantages

1. Specialized in manufacturing iron cores for 15 years, and exporting related components for more than 10 years.

2. Obtained ISO9001, IATF16949 and other certifications.

3. Short delivery time.

4. Competitive price.

5, Equipped with automatic powder spraying line.

6. Welcome to customize orders.

Are you looking for a powerful and efficient motor for your industrial, commercial or consumer electronic application? Look no further than our DC motors, designed with a stator and rotor for reliable and high-performance operation.

Our DC motors offer many advantages, including high efficiency, high torque, a simple design, a wide range of speeds, and a long lifespan. Whether you need a motor for automotive, robotics, aerospace, industrial automation, medical devices or consumer electronics, our DC motors can meet your needs.

We take pride in our commitment to quality and reliability, ensuring that every motor we manufacture meets the highest standards of performance and durability. Our team of experts is also available to provide personalized support and assistance, helping you select the right DC motor for your specific application.

Don't settle for anything less than the best. Choose our DC motors with stator and rotor design for powerful, efficient and reliable operation. Contact us today to learn more and place your order.

Our services

1. Have a strong R&D team.

2. Quickly respond to your inquiries and feedback.

3, good quality, strict quality control.

4. Professional after-sales team.

We look forward to working with you!

Stators and rotors are essential components of DC motors, responsible for converting electrical energy into mechanical motion. At CHME Components Co., Ltd., we specialize in the high-speed stamping and insulation coating of stator and rotor cores for DC motors. Our custom stator and rotor solutions are tailored to the specific needs of our clients, providing reliable and efficient performance for a wide range of applications.

Our stator and rotor cores are manufactured using state-of-the-art stamping technology and high-quality materials, ensuring the highest levels of precision and consistency. We offer a wide range of sizes and shapes for stators and rotors for DC motors, which can be customized to meet your specific requirements.

Our manufacturing process is optimized for cost-effectiveness, enabling us to offer competitive pricing without sacrificing quality. We have extensive experience working with international companies for over 10 years, ensuring that our products meet the highest standards of quality and reliability.

Whether you need a custom stator and rotor for a new DC motor design or a replacement for an existing motor, CHME is here to help. Contact us today to learn more about our stator and rotor solutions for DC motors, and let us help you achieve your goals with superior performance and reliability.