Stators for BLDC Motors

Product origin: guangdong Specification: O.D. Ф110x I.D. Ф15

Product Description

Stators for BLDC Motors: Enhancing Efficiency and Performance

Introduction

Welcome to our comprehensive guide on stators for BLDC (Brushless DC) motors. As industry leaders in manufacturing high-quality stators, we are here to provide you with in-depth information about these crucial components. We sell best . If you want to wholesale high quality Stators for BLDC Motors, you can browse the product details and to get a quote.

Specification

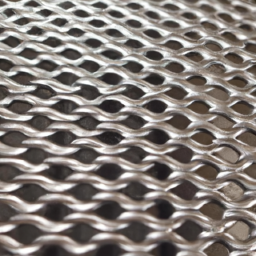

| Describe | Coating brushless motor cores |

| Types Of | Epoxy coating (epoxy resin coating) |

| Application | DC brushless motor |

| Processing | stamping |

| Material | Silicon steel |

| Weight Range | 0.5-100Kg |

| Design Support | AutoCAD, Solidworks, PDF |

| Quality Control | Materials, Dimensions, Properties, Internal Defects, Balance Tests |

| Standard | ASTM, DIN, JIS, ISO, GB standard |

Main Application: apply to BLDC motors

Understanding BLDC Motors

Before we delve into the specifics of stators, let's take a moment to understand the fundamental principles of BLDC motors. BLDC motors are electric motors that operate using a permanent magnet rotor and a stator with windings. They are widely recognized for their efficiency, reliability, and precise control, making them the preferred choice in various industries.

The Role of Stators in BLDC Motors

Stators play a vital role in the overall performance and efficiency of BLDC motors. They consist of a core made of laminated steel sheets and windings that generate magnetic fields. The stator windings are strategically placed to create a rotating magnetic field, which interacts with the permanent magnet rotor to produce rotational motion.

Superior Design and Manufacturing

To ensure optimal performance and longevity, our stators are designed and manufactured with the utmost precision. We employ advanced techniques and cutting-edge technologies to deliver stators that surpass industry standards. Here are some key factors that set our stators apart:

1. High-Quality Materials

We source only the finest materials for our stators, carefully selecting high-grade laminated steel sheets and superior-quality copper windings. These materials are chosen for their excellent magnetic properties, low energy loss, and exceptional thermal conductivity.

2. Advanced Winding Techniques

Our stators incorporate advanced winding techniques that maximize efficiency and minimize electrical losses. Through meticulous attention to detail during the winding process, we ensure consistent and uniform distribution of magnetic fields, resulting in enhanced motor performance.

3. Robust Insulation

To guarantee reliable operation even under demanding conditions, our stators feature robust insulation. The insulation materials provide excellent electrical insulation and protect the windings from moisture, temperature fluctuations, and other potential sources of damage.

Benefits of Our Stators for BLDC Motors

Investing in our stators offers numerous benefits for your BLDC motors. Let's explore the advantages that set our stators apart from the competition:

1. Improved Efficiency

Our stators are designed to maximize motor efficiency by minimizing energy losses and reducing heat generation. This results in improved overall system efficiency, reduced power consumption, and lower operating costs.

2. Enhanced Performance

With our high-quality stators, you can experience superior motor performance. The precision-engineered design and optimized magnetic fields ensure smooth and reliable operation, providing increased torque, speed, and responsiveness.

3. Extended Lifespan

Durability is a hallmark of our stators. The use of top-grade materials, robust insulation, and meticulous manufacturing processes contribute to their exceptional lifespan. By choosing our stators, you can minimize maintenance requirements and enjoy prolonged motor longevity.

4. Customization Options

We understand that different applications have specific requirements. That's why we offer customization options for our stators. Whether it's a particular winding configuration, size, or other specifications, our team can tailor stators to meet your unique needs.

Applications of Stators for BLDC Motors

Our high-performance stators find wide applications across various industries. Some notable applications include:

1. Electric vehicles (EVs) and hybrid electric vehicles (HEVs)

2. Industrial automation and robotics

3. HVAC systems

4. Aerospace and aviation

5. Renewable energy systems

Advantage

1. Specialized in manufacturing iron cores for 15 years, and exporting related components for more than 10 years

2. Obtained ISO9001,IATF16949 and other certifications

3. Short delivery time

4. Competitive price

5, equipped with automatic powder spraying line

6. Welcome to customize orders

Our service

1. Have a strong R&D team

2. Quickly respond to your inquiries and feedback

3, good quality, strict quality control

4. Professional after-sales team

Conclusion

In conclusion, stators for BLDC motors play a critical role in achieving optimal performance, efficiency, and reliability. By choosing our high-quality stators, you can elevate the capabilities of your motor systems and enjoy the benefits of improved efficiency, enhanced performance, and extended lifespan. to learn more about our stators and how they can contribute to the success of your applications.