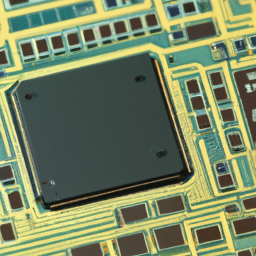

On-Line Copper Thickness Inspection Machine

Introducing our cutting-edge On-Line Copper Thickness Inspection Machine – the ultimate solution for ensuring precise and accurate copper thickness measurements!

Product Description

zhengye are exported all over the world and different industries with quality first. Our belief is to provide our customers with more and better high value-added products. Let's create a better future together.

Introducing our cutting-edge On-Line Copper Thickness Inspection Machine – the ultimate solution for ensuring precise and accurate copper thickness measurements! With our state-of-the-art technology, we have revolutionized the copper inspection process, allowing you to effortlessly monitor and maintain the quality of your copper materials.

Unparalleled Precision:

Our On-Line Copper Thickness Inspection Machine is equipped with advanced sensors and cutting-edge software, enabling it to measure copper thickness with unparalleled precision. Say goodbye to manual measurements and unreliable guesswork – our machine will provide you with precise readings every single time. With a high level of accuracy, you can rest assured that your copper materials meet the required specifications, saving you time, money, and eliminating wastage.

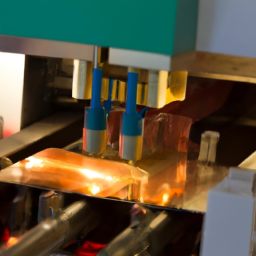

Streamlined Efficiency:

We understand the importance of efficiency in your production line. Our On-Line Copper Thickness Inspection Machine is engineered to seamlessly integrate into any manufacturing process, allowing you to maintain a smooth workflow. With real-time measurements and automated data logging, you can monitor your copper thickness levels instantaneously, identifying any deviations and taking prompt corrective actions when necessary. This not only minimizes downtime but also ensures consistent quality control, enhancing your overall operational efficiency.

Quality Assurance:

When it comes to copper materials, quality is paramount. Our On-Line Copper Thickness Inspection Machine ensures that your products consistently meet the highest standards. By utilizing its cutting-edge technology, you can detect even the slightest variations in copper thickness, ensuring the uniformity and integrity of your materials. By eliminating defects early in the production process, you can deliver flawless products to your customers, effectively enhancing your brand reputation and customer satisfaction.

Time and Cost Savings:

Investing in our On-Line Copper Thickness Inspection Machine means investing in long-term cost savings. With accurate measurements, you can optimize your material usage, reducing waste and minimizing unnecessary expenses. Additionally, the machine's automated features eliminate the need for tedious manual measurements, saving you valuable time and allowing your workforce to focus on other essential tasks. By streamlining your inspection process, you can significantly increase productivity and reduce overall production costs.

User-Friendly Interface:

Navigating our On-Line Copper Thickness Inspection Machine is a breeze. With its intuitive user interface and easy-to-understand controls, you can operate the machine effortlessly, regardless of your technical expertise. The machine also offers customizable settings, tailoring the inspection process to your specific requirements. Its user-friendly approach ensures that anyone can operate the machine with ease, promoting efficiency and reducing the need for extensive training.

Invest in your production line's success with our On-Line Copper Thickness Inspection Machine. With its unparalleled precision, streamlined efficiency, quality assurance, time and cost savings, and user-friendly interface, this cutting-edge technology will undoubtedly enhance your copper inspection process. Don't compromise on quality – choose our machine and guarantee superior products that meet your customers' exacting needs.

For more Zhengye Technology's X Ray Counterinformation, please contact us. We will provide professional answers.