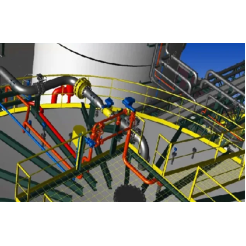

Oil Flushing System

An oil flushing system is a process used to clean out and remove contaminants from hydraulic and lubrication systems. It typically involves using a retro jetting or hydro jetting pipes to pump a high-pressure stream of oil through the system, effectively scouring the interior surfaces to dislodge any built-up debris.

Product Description

An oil flushing system is a process used to clean out and remove contaminants from hydraulic and lubrication systems. It typically involves using a retro jetting or hydro jetting pipes to pump a high-pressure stream of oil through the system, effectively scouring the interior surfaces to dislodge any built-up debris. The oil and contaminants are then flushed out of the system, leaving it clean and ready for use. This process is often performed by oil flushing service providers, who have the expertise and equipment necessary to perform the task safely and efficiently.

Benefits of Hot Oil Flushing

Hot oil flushing is a process of cleaning and flushing out contaminants and debris from the inside of pipelines, heat exchangers, and other equipment using heated oil. Some of the benefits of hot oil flushing include:

Improved system efficiency: Hot oil flushing can help remove debris and contaminants that can impair system performance, resulting in improved efficiency and reduced energy consumption.

Reduced maintenance costs: By removing debris and contaminants, hot oil flushing can help reduce the frequency of maintenance and repair activities, which can lead to lower costs over time.

Extended equipment life: Hot oil flushing can help prevent corrosion and other forms of damage to equipment, thereby extending its useful life.

Reduced downtime: Hot oil flushing can be performed quickly and efficiently, which can help reduce system downtime and minimize the impact on operations.

Enhanced safety: By removing debris and contaminants, hot oil flushing can help prevent equipment failure and other safety hazards, reducing the risk of accidents and injuries.