GM Mechanical Diaphragm Dosing pump

Product Description

Introduction:

1.Cast aluminum shell with high heat dissipation performance and lightweight, suitable for various acidic and alkaline solutions.

2.Non-toxic and odorless.

3.Adopts cam mechanism and completely leak-free, can be placed in a tank or pipeline.

4.The pump head where contact medium made of PVC, optional PTFE, stainless steel, aluminum alloy, etc.

5.Cost-effective and widely used in water treatment industries with low pressure requirements.

6.The flow rate can be adjusted at any time during pump operation or stop, and it can also be quantitatively output.

7.The diaphragm is made of a multi-layer composite structure, with the first layer being an acid-resistant Teflon film, the second layer being EPDM elastic rubber, the third layer being a 3mm thick SUS304 supporting iron core, the fourth layer being reinforced with nylon fibers, and the fifth layer being completely covered with EPDM elastic rubber, effectively improving the service life of the diaphragm.

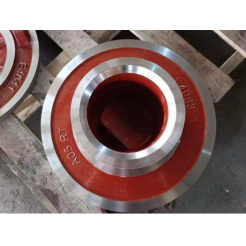

Structure:

The pump consists of three parts: motor, transmission box, and cylinder body.

The transmission box component is composed of a bow-shaped connecting rod cam mechanism, stroke adjustment mechanism, and speed ratio worm mechanism; the high stroke adjustment is achieved by rotating the adjustment handwheel, which changes the front and back distance in the bow-shaped connecting rod to change the stroke of the plunger (piston).

The cylinder body component is composed of a pump head, suction valve assembly, discharge valve assembly, plunger, and packing seal.

Basic installation and fixing elements:

The liquid and solid content should not exceed 5%, and the particle diameter should not exceed 1mm.

The installation height of the pump should not exceed 7 meters from the liquid level.

The pump inlet pipe should be made of hard plastic or metal material, and ensure that there is no damage, leakage, or air leakage in the pipe when connected.

Features:

1.The pump has excellent performance, with the diaphragm metering pump absolutely leak-proof, high safety performance, accurate metering and delivery, flow can be arbitrarily adjusted from zero to the maximum quota value range, and pressure can be arbitrarily selected from atmospheric pressure to the maximum allowable range.

2.The adjustment is intuitive and clear, stable, noiseless, small in volume, light in weight, easy to maintain, and can be used in parallel.

3.The pump has a wide variety of products, full performance, and is suitable for conveying -30 degrees to 450 degrees, with viscosity of 0-800mm/s. The maximum discharge pressure can reach 64Mpa, the flow range is 0.1-20000L/h, and the metering accuracy is within ±1%.

4.According to process requirements, the pump can be adjusted manually and with variable frequency to adjust the flow, and can also be remotely controlled and computer-automatically controlled.

Performance table

|

Pump Model |

Flow rate L/h |

Pressure Mpa |

SPM min |

Power KW |

Inlet/Outlet DN |

Weight kg |

|

GM-25/1.2 |

25 |

1.2 |

48 |

0.37 |

Φ8 tube |

18 |

|

GM-50/1.2 |

50 |

1.2 |

48 |

0.37 |

Φ8 tube |

|

|

GM-80/1.0 |

80 |

1 |

96 |

0.37 |

15 |

|

|

GM-120/0.7 |

120 |

0.7 |

48 |

0.37 |

15 |

|

|

GM-170/0.7 |

170 |

0.7 |

96 |

0.37 |

15 |

|

|

GM-200/0.3 |

200 |

0.3 |

96 |

0.55 |

20 |

|

|

GM-320/0.5 |

320 |

0.5 |

144 |

0.37 |

20 |

20 |

|

GM-450/0.5 |

450 |

0.5 |

144 |

0.55 |

25 |

|

|

GM-500/0.5 |

500 |

0.5 |

144 |

0.55 |

25 |

Installation Dimension:

Email: info@topslurrypump.com

Tel.: +86 138 3115 3172

Skype: jenny.006

Whatsapp: +8613831153172

Add.: No.150 Donggang Road, Yuhua Destrict, Shijiazhuang, China