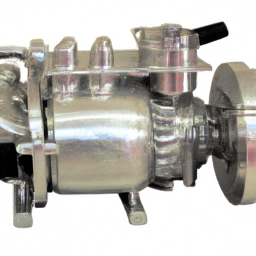

VS Vertical Slurry Pump

Vertical Slurry Pump is a cantilever sump pump,which work submerged to transport high abrasive and high density slurries with large particles.Slurry Pump Vertical doesn't need any seal water.Hard metal lined or fully rubber lined fitted.High capacity double suction semi-open impeller design.Suction agitator is also available.This pump serves as an alternative to SP Vertical Slurry Pumps.

Product Description

The VS Vertical Slurry Pump by DeShi is a highly efficient and reliable pumping solution designed for handling abrasive and corrosive slurries in various industrial applications. It features a vertical spindle design that ensures optimal performance and durability, making it a preferred choice for customers seeking top-quality vertical spindle pump suppliers.

Size (discharge): 40mm to 300mm

Capacity: 7.28-1300 m3/h

Head: 3m-45 m

Handing solids: 0-79mm

Concentration: 0%-70%

Materials: High chrome alloy, Rubber

、

The VS Vertical Slurry Pump is a type of centrifugal pump specifically designed for handling abrasive and corrosive slurries. It features a vertical spindle design, where the impeller is mounted on a vertical shaft. This vertical configuration allows the pump to be submerged directly into the slurry, eliminating the need for priming and providing a compact footprint.

The vertical spindle design offers several advantages for slurry pumping applications. It allows for efficient handling of thick and heavy slurries with high concentrations of solids. The pump's vertical orientation also helps to reduce the risk of airlocks and clogging, ensuring continuous and reliable operation.

Vertical slurry pumps are commonly used in industries such as mining, mineral processing, dredging, power generation, chemical processing, and wastewater treatment. Warman Vertical Sump Pumps are suitable for pumping slurries containing abrasive particles, such as sand, gravel, coal, ores, and various minerals.

These pumps are designed to withstand the harsh conditions typically encountered in slurry pumping, including erosive wear, corrosion, and high-pressure environments. Warman Vertical Sump Pumps are constructed with durable materials and often feature wear-resistant components, such as high-chrome alloys or rubber linings, to extend their service life.

Selection Chart and General Curve

This VS Vertical Slurry Pumps serves as an alternative to Warman SP Vertical Slurry Pumps.

|

DeShi Model |

Warman Model |

Max. Motor Power |

Material |

Range of Clear Water Performance |

Impeller |

|||||||

|

Liner |

Impeller |

Flow Rate Q

|

Head (m) |

Speed RPM |

Max. Eff (%) |

NPSH (m) |

Vanes No. |

Dia. φ(mm) |

||||

|

(m³/h) |

(L/s) |

|||||||||||

| 40VS-PV |

40PV-SP |

M |

M |

15 |

19.44-43.2 |

5.4-12 |

4.5-28.5 |

1000-2200 |

40 |

|

5 |

188 |

|

R40VS-PV |

40PV-SPR |

R |

R |

17.28-39.6 |

4.8-11 |

4-26 |

1000-2200 |

40 |

|

5 |

188 |

|

|

65VS-QV |

65QV-SP |

30 |

M |

M |

23.4-111 |

6.5-30.8 |

5-29.5 |

700-1500 |

50 |

|

5 |

280 |

|

R65VS-QV |

65QV-SPR |

R |

R |

22.5-105 |

6.25-29.15 |

5.5-30.5 |

700-1500 |

51 |

|

5 |

280 |

|

|

100VS-RV |

100RV-SP |

75 |

M |

M |

54-289 |

15-80.3 |

3-35 |

500-1200 |

56 |

|

5 |

370 |

|

R100VS-RV |

100RV-SPR |

R |

R |

64.8-285 |

18-79.2 |

7.5-36 |

600-1200 |

62 |

|

5 |

370 |

|

|

I50VS-SV |

150SV-SP |

110 |

M |

M |

108-470.16 |

30-133.1 |

8.5-40 |

500-1000 |

52 |

|

5 |

450 |

|

200VS-SV |

200SV-SP |

110 |

M |

M |

189-891 |

152.5-247.5 |

6.5-37 |

400-850 |

64 |

|

5 |

520 |

|

250VS-TU |

250TU-SP |

200 |

M |

M |

261-1089 |

72.5-302.5 |

7.5-33.5 |

400-750 |

60 |

|

5 |

575 |

|

300VS-TU |

300TU-SP |

200 |

M |

M |

288-1267 |

80-352 |

6.5-33 |

350-700 |

50 |

|

5 |

610 |

The VS Vertical Slurry Pump serves as a compelling alternative to the Warman SP Vertical Slurry Pump series. The VS Vertical Slurry Pump stands out as an excellent choice for businesses seeking a cost-effective solution for their slurry pumping needs. Offering affordability without compromising on quality, this pump is a game-changer in the industry.One of its standout features is its seamless interchangeability with the Warman SP Vertical Slurry Pump series. This means that users can easily transition from Warman to the VS pump without the hassle of extensive modifications or adjustments to their existing setup.Rest assured that the VS Vertical Slurry Pump maintains high-quality standards. It is built to withstand the demanding conditions of slurry pumping applications, ensuring reliable and consistent performance over time.With the VS pump, you can count on dependable and consistent performance, which is crucial for keeping operations running smoothly. Reduced maintenance costs add to the appeal, making it a cost-effective long-term solution.The VS Vertical Slurry Pump offers customization options to match the specific requirements of your application. This flexibility ensures that you get a pump that suits your needs perfectly, avoiding unnecessary expenses.Choosing the VS Vertical Slurry Pump can lead to substantial cost savings. Not only is it competitively priced, but its durability and efficiency also result in reduced operational and maintenance costs, making it a smart investment.

Assembly Structure

Structure & Spares

|

Metal Lined Vertical Slurry Pump |

Rubber Lined Vertical Slurry Pump |

||||

|

No |

Parts name |

Materials |

No |

Parts name |

Materials |

|

1 |

Shaft |

45 High Strength Steel |

1 |

Shaft |

45 High Strength Steel |

|

2 |

Bearing |

China Brand or SKF; NSK |

2 |

Bearing |

China Brand or SKF; NSK |

|

3 |

Bearing Housing |

Ductile Cast Iron |

3 |

Bearing Housing |

Ductile Cast Iron |

|

4 |

Bearing spacer |

Stainless Steel |

4 |

Bearing spacer |

Stainless Steel |

|

5 |

Bearing |

China Brand or TIMKEN; SKF |

5 |

Bearing |

China Brand or TIMKEN; SKF |

|

6 |

Shim |

Stainless steel |

6 |

Shim |

Stainless steel |

|

7 |

Column |

Stainless steel |

7 |

Column |

Stainless steel |

|

8 |

Strainer |

Cast Iron |

8 |

Strainer |

Natural Rubber |

|

9 |

Back liner |

Ultra Chrome Alloy |

9 |

Back liner |

Anti-abrasive Rubber |

|

10 |

Impeller |

Ultra Chrome Alloy |

10 |

Impeller |

Anti-abrasive Rubber |

|

11 |

Pump casing |

Ultra Chrome Alloy |

11 |

Pump casing |

Anti-abrasive Rubber |

|

12 |

Lower strainer |

Cast Iron |

12 |

Lower strainer |

Natural Rubber |

|

13 |

Discharge pipe |

Stainless steel |

13 |

Discharge pipe |

Stainless steel |

|

14 |

Flushing pipe |

Carbon steel |

14 |

Flushing pipe |

Carbon steel |

|

15 |

Coupling |

45# Steel |

15 |

Coupling |

45# Steel |

|

16 |

Middle supporting parts |

Stainless steel |

16 |

Middle supporting parts |

Stainless steel |

Click to view more slurry pump components.

Design features:

1. Vertical, Submerged, Cantilevered shaft sump slurry pump

2. Bearing Assembly - The bearings, shaft and housing are generously proportioned to avoid problems associated with the operation of cantilevered shafts in the first critical speed zones.

3. Column Assembly - Completely fabricated from anti-wear carbon steel. The VSR model is rubber covered.

4. Shaft - Different length of the pump drive shaft or suction extension pipe could be selected.

5. Casing - VS(R) has a simple bolt-on attachment to the base of the column. It is manufactured from a wear resistant alloy for the VS pump series and from moulded Rubber for the VSR pump series.

6. Impeller - Double suction semi-open impeller design, Wear resistant alloys, polyurethane and moulded elastomer impellers are interchangeable.

7. Upper Strainer - Drop-in metal mesh; snap-on elastomer or polyurethane for VS and VSR pumps. Strainers fit in column openings.

8. Lower Strainer - Bolted metal or polyurethane for VS pumps; moulded snap-on elastomer for VSR pumps.

9. Discharge Pipe - Metal for VS pumps; Rubber covered for VSR pumps. All wet metal parts are completely rust protected.

10. Agitator option keeps solids in suspension, Alternatively, a mechanical agitator is fitted to an extended shaft protruding from the impeller eye.

11. Don’t need any seal and seal water.

Outline Dimensions

Key Features:

♦Vertical Spindle Design: The VS Vertical Slurry Pump incorporates a vertical spindle design, which allows for seamless operation and efficient handling of slurries. This design feature ensures improved performance, reduced maintenance, and increased overall pump lifespan.

♦Robust Construction: Crafted with high-quality materials, the VS Vertical Slurry Pump offers exceptional strength and durability, enabling it to withstand the harshest operating conditions. It is designed to handle abrasive and corrosive slurries with ease, providing long-lasting performance.

♦High Efficiency: With its advanced hydraulic design, the VS Vertical Slurry Pump delivers high efficiency and energy savings. It is engineered to maximize flow rates while minimizing power consumption, resulting in reduced operating costs for the end user.

♦Easy Maintenance: DeShi, renowned vertical spindle pump suppliers, have ensured that the VS Vertical Slurry Pump is easy to maintain. Its modular design allows for quick and hassle-free access to key components, simplifying inspection, servicing, and repairs.

♦Versatile Applications: The VS Vertical Slurry Pump is suitable for a wide range of applications, including mining, mineral processing, chemical processing, dredging, and many more. It is designed to handle abrasive and corrosive slurries containing solids of varying sizes.

♦Customizable Options: DeShi understands that each customer has unique requirements. Hence, the VS Vertical Slurry Pump can be customized to meet specific application needs, including material options, impeller types, and sealing arrangements.

♦Comprehensive Support: As trusted vertical spindle pump suppliers, DeShi offers comprehensive customer support services. From pump selection assistance to technical guidance and after-sales support, DeShi is committed to ensuring customer satisfaction throughout the entire product lifecycle.

The VS Vertical Slurry Pump serves as a cost-effective and reliable alternative to the Warman SP Vertical Slurry Pump series. Its affordability, compatibility, and quality make it a standout choice for businesses looking to optimize their slurry pumping operations without breaking the bank.

When it comes to vertical spindle pump suppliers, DeShi's VS Vertical Slurry Pump stands out as a reliable, efficient, and versatile solution. Its vertical spindle design, robust construction, and high-performance capabilities make it the ideal choice for handling abrasive and corrosive slurries in various industries. Trust DeShi for exceptional products and comprehensive customer support.