difference between gate valve and knife gate valve

Product Description: Gate Valve vs

Product Description

Product Description: Gate Valve vs. Knife Gate Valve

Introducing the Ultimate Flow Control Solutions: Gate Valves and Knife Gate Valves

When it comes to controlling the flow of liquids and slurries, choosing the right valve is crucial. Our Gate Valves and Knife Gate Valves stand at the forefront of engineering excellence, providing you with reliable solutions tailored to your unique needs. Let's explore the differences between these two exceptional products, highlighting their specifications, advantages, and applications.

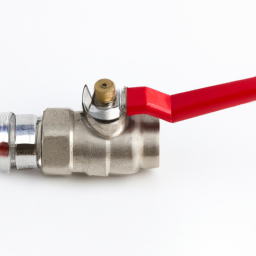

Gate Valve: Reliable and Versatile

Specifications:

- Dimensions: Available in sizes ranging from 1" to 48"

- Pressure Rating: Up to 1500 PSI

- Material Options: Carbon steel, stainless steel, brass, and more

- Temperature Range: Suitable for applications up to 400°F (200°C)

Key Features:

- Sealing Performance: Designed with a resilient and tightly-sealed closure that ensures zero leakage, making it ideal for high-pressure systems.

- Versatility: Perfect for on/off applications, whether in water treatment, oil and gas, or chemical processing industries.

- Longevity: Robust construction ensures durability and reliability over extended periods, reducing maintenance costs.

Applications:Gate valves are perfect for applications requiring a straight-line flow and minimal pressure drop, including:

- Water supply systems

- HVAC applications

- Oil and gas pipelines

Knife Gate Valve: The Solution for Abrasive and Slurry Applications

Specifications:

- Dimensions: Available in sizes from 2" to 36"

- Pressure Rating: Up to 300 PSI

- Material Options: Cast iron, stainless steel, and plastic lined for specialized environments

- Temperature Range: Suitable for temperature extremes from -40°F to 300°F (-40°C to 150°C)

Key Features:

- Designed for Slurries: The sharp blade of the knife gate valve easily cuts through sludges, slurries, and thick fluids, providing a clean closure with minimal resistance.

- Quick Operation: Designed for fast opening and closing, knife gate valves increase operational efficiency and reduce downtime.

- Compact Design: Space-saving design makes them ideal for constricted installations, making it easier to implement in existing systems.

Applications:Ideal for industries dealing with abrasive materials or difficult-to-handle fluids:

- Pulp and paper manufacturing

- Mining and mineral processing

- Wastewater treatment plants

Choose the Right Valve for Your Needs

Understanding the difference between gate valves and knife gate valves is essential for ensuring optimal performance in your applications. While gate valves excel in overall versatility and pressure handling, knife gate valves offer unmatched performance in abrasive conditions and slurries.

Why Choose Us?Our extensive product line is engineered with precision, ensuring compliance with the highest industry standards. With a focus on customer satisfaction, we provide personalized consultations to help you find the perfect valve solution tailored to your unique operational requirements.

Take Action Today!Don't let flow control challenges slow you down. Elevate your operations with our superior gate valves and knife gate valves. Explore our extensive product range, schedule a consultation, or request a quote now. Experience the reliability and efficiency that our products bring to your business, and let us help you achieve seamless control over your systems!

Contact Us Today and Transform Your Operations!

Related Products:difference between gate valve and knife gate valve, difference between butterfly valve and gate valve