10-20HL / 10-20BBL Craft Brewery System

Turnkey craft brewery of 20hl from ZYBREW is most customized as the basic request on beer brewing from client and the existing building. Or we do turnkey solution design from Greenland. The brewhouse efficiency range from 2-8 brews based on different preferred configuration.

Product Description

10-20HL / 10-20BBL Craft Brewery System

Specification

Turnkey craft brewery of 20hl from ZYBREW is most customized as the basic request on beer brewing from client and the existing building. Or we do turnkey solution design from Greenland. The brewhouse efficiency range from 2-8 brews based on different preferred configuration.

The design and fabrication are both following what is more suitable for local requests, to make sure client has less extra cost on other issues when running the brewery. We make operating the system for brewing easier and more efficient the priority, meanwhile we try our best to lower the cost of materials and save energy, to help all clients all over the world find the best balance between investment and income.

● Higher wort wort extract

● Lower energy cost and material consumption

● Well adjusted temp and water blending unit for better grain and water mixing

● Special designed steam jacket unit to increase steam using efficiency and avoid “water hammer” problem

● Special tank and piping construction to avoid the wort aeration problem and decrease the material lost

● Internal heater for separate kettle, working with cylinder and bottom jacket for better boiling effect.

● Possible to make boiling process under pressure, especially for brewery at higher altitudes.

● Special designed steam condensing unit, with both steam condensing and water heating function

● Cellar tanks with good design updating for better cooling effect and accurate temp control

● Pre assembled cellar piping, with cat walks for operation on top or manifold or piping corridor

● Cooling unit for current use and well prepared for future expanding

● Automation system with curve indication and production record printing, with recipe storage function, clients can create new recipe as the exact production requirement.

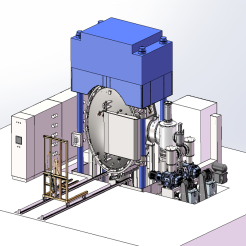

Brewing System Basic configuration:

● Grain handling: Mill, conveyor (flexi auger or chain disc), hopper etc. With weight scaling

● Brewhouse: Three or four vessels, including piping, HE etc.

● Cellar: Fermenter, storage tank and BBTs, for fermentation of different kinds of beer, all assembled and isolated

● Cooling: Chiller connected with glycol tank for cooling, with ice water tank and plat cooler for wort cooling

● CIP: Fixed CIP station or Portable CIP unit

● Filtration: Diatomite filtration, membrane filter, Plate frame filtration unit etc.

● Compressed air unit and N2 generator, all piping lines connected with system

Optional:

● Bottling line range from 500-2000bph.

● Kegging unit: Keg filler & keg washer, or combined machine

● Automation: Fully automation possible from Proleit

● Wet milling system typically designed for micro brewery

Our 10 bbl Brewing System is a production-scale brewing system that brings your beer to market. If you're planning to build a medium to large brewpub, microbrewery, brewery or distribution center, this 10-barrel multi-vessel beer brewing system is for you.

At ZYBREW, our Craft Brewery are turnkey and offer several advantages over our competitors.