Sand Gravel Pump

Sand Gravel Pump - the perfect solution for all your pumping needs! This high-performance pump is specifically designed to handle abrasive materials such as sand, gravel, and other solids with ease, making it the ideal choice for applications in the mining, construction, and dredging industries.Order yours today and experience the power and performance of this exceptional pump!

Product Description

At DeShi, we are committed to providing our customers with high-quality Sand Gravel Pumps that meet their specific requirements. As a leading Sand Gravel Pump supplier in China, we offer a wide range of pumps that are designed to deliver superior performance and reliability. Our Sand dredge pump for sale options are a popular choice for customers looking for cost-effective pumping solutions.

Model Meaning

Sand Gravel Pump Introduction:

Type G and GH pumps are single-stage, single-suction, cantilevered, horizontal, centrifugal slurry pump .They are designed for continuously handling the most difficult higher abrasive slurries which contain too big solids to be pumped by common pumps. They are suitable for delivering slurries in mining, explosive sludge in metal melting, dredging in dredger and course of rivers, and other filed. This Sand Gravel Pump especially suitable for the high flow, high concentration and high head working condition, good performance of NPSH and high abrasion- resistant, can be widely used in high temperature and strong abrasive slurry transportation.

The wet parts are made of wear resistant high-Chrome alloys to ensure long service life. It has superior performance than common pumps in dredging, sand mining, barge loading and mineral processing etc. DGH gravel pump has achieved extra high head for special working conditions.

Gravel Pump Diameter: 4"〜20

Capacity to: 5600m3/hr

Head to: 78m

China Sand Gravel Pump

If you're looking for a reliable Sand Gravel Pump supplier in China, look no further than DeShi. Contact us today to learn more about our range of Sand Gravel Pumps and how we can help you with your pumping requirements.

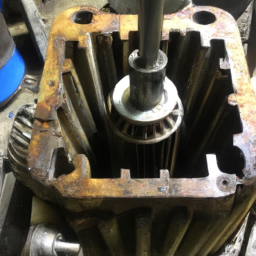

Gravel/Sand Pump Structure

Our submersible sand pump agitator is a powerful pumping solution that combines a submersible pump and an agitator, making it ideal for dredging, excavating, and mining applications. The agitator ensures that the pump can handle heavy and viscous slurries with ease, while the submersible design allows for easy installation and maintenance.

With its rugged construction and durable components, the Sand Gravel Pump is built to withstand the toughest operating conditions. Featuring a large impeller and casing, this pump is capable of delivering high volumes of material over long distances, making it an efficient and reliable choice for your pumping requirements.

Sand Gravel Pump Design Features

1. Gravel Sand pump (dredge pump) is designed as single casing connected by means of clamp bands and wide wet-passage.

2. The wearing parts are made of ultra chromium abrasion-resistance alloys, long service life and very low failure rate.

3. The Sand Gravel Pumps are designed for continuously transferring strong corrosive big-solid -contained slurry which the common slurry pump cannot transfer. They are widely used in dredging, sand excavation; mining, explosive-sludge in metal melting, etc..

4. DG series gravel pump is often installed on cutter suction dredger or barge.

5. Gravel pump outlet direction can be in any position of 360· This type of pump possesses the advantages of easy installation and operation, good performance of NPSH and abrasion resistance.

6. The discharge direction of gravel pump can be oriented in any direction of 360°

Our sand and gravel pump range is designed to deliver high-volume pumping of sand and gravel over long distances. These pumps are ideal for construction sites, mining operations, and other applications that require the transfer of large volumes of material.

Our gravel dredge pump range is specifically designed for dredging applications, making it the ideal choice for dredging rivers, lakes, and other bodies of water. With their rugged construction and durable components, our gravel dredge pumps are built to withstand the toughest operating conditions.

The Gravel pump is equipped with a heavy-duty motor and is designed for easy maintenance, with quick and simple access to all internal components. This means that downtime is minimized, and maintenance costs are reduced, ensuring maximum productivity and profitability.

Sand Gravel Pump Characteristics

DG & DGH Gravel Pump Performance Parameters (Only for primary selection)

|

Sand PUMP Model

|

PERFORMANCE |

|||||

|

Max Power |

Flow Rate m3/h |

HEAD H(m) |

SPEED (r/min) |

ALLOWABLE MAX. SOLIDS SIZE (mm) |

NPSH (m) |

|

|

6/4D-G |

60 |

36-252 |

3.5-51 |

600-1400 |

82 |

2.5-3.5 |

|

8/6E-G |

120 |

137-580 |

10-48 |

800-1400 |

127 |

3.0-4.5 |

|

10/8F-G |

260 |

220-1000 |

13-50 |

500-1000 |

178 |

3.0-7.5 |

|

10/8S-G |

560 |

220-1000 |

13-50 |

500-1000 |

178 |

3.0-7.5 |

|

12/10F-G |

260 |

360-1520 |

11-58 |

400-850 |

220 |

2.0-4.5 |

|

12/10G-G |

600 |

360-1520 |

11-58 |

400-850 |

220 |

2.0-4.5 |

|

14/12G-G |

600 |

500-3100 |

6-66 |

300-700 |

241 |

2.0-8.0 |

|

16/14G-G |

600 |

650-3610 |

9-48 |

250-500 |

254 |

3.0-6.0 |

|

18/16G-G |

600 |

860-3800 |

9-48 |

250-500 |

330 |

3.0-6.0 |

|

18/16T-G |

1200 |

860-3800 |

9-48 |

250-500 |

330 |

3.0-6.0 |

|

10/8S-GH |

560 |

400-1290 |

18-80 |

500-950 |

180 |

2.0-5.0 |

|

12/10G-GH |

600 |

600-2200 |

28-78 |

350-700 |

210 |

2.0-8.0 |

The Outline dimensions of Sand Gravel Pump

|

Pump Model |

Outline Dimensions |

Anchor Hole |

Suction Flange |

Discharge Flange |

Weight (kg) |

||||||||||||||||

|

A |

B |

C |

D |

E |

F |

G |

H |

L |

M |

N |

P |

T |

N-d |

D1 |

D2 |

N-d1 |

D3 |

D4 |

N-d2 |

||

|

DG6-4D |

1006 |

432 |

432 |

213 |

213 |

330 |

289 |

54 |

203 |

343 |

260 |

330 |

16 |

4-φ22 |

260 |

305 |

8-φ19 |

210 |

254 |

4-φ19 |

460 |

|

DG8-6E |

1286 |

546 |

546 |

257 |

257 |

392 |

365 |

75 |

295 |

405 |

352 |

457 |

54 |

4-φ29 |

324 |

368 |

8-φ19 |

210 |

254 |

4-φ19 |

1120 |

|

DG10-8F |

1591 |

857 |

762 |

349 |

349 |

487 |

540 |

98 |

330 |

533 |

416 |

610 |

60 |

4-φ35 |

406 |

457 |

8-φ19 |

210 |

254 |

4-φ19 |

2250 |

|

DG12-10F |

1702 |

883 |

762 |

584 |

584 |

411 |

705 |

98 |

368 |

667 |

522 |

610 |

-3 |

4-φ35 |

470 |

527 |

8-φ19 |

210 |

254 |

4-φ19 |

3320 |

|

DG10-8S |

1720 |

920 |

760 |

640 |

640 |

373 |

780 |

90 |

330 |

533 |

416 |

450 |

-102 |

4-φ35 |

406 |

457 |

8-φ19 |

210 |

254 |

4-φ19 |

2285 |

|

DG12-10G |

2010 |

1207 |

851 |

749 |

749 |

473 |

876 |

152 |

368 |

665 |

522 |

851 |

238 |

4-φ41 |

470 |

527 |

8-φ19 |

210 |

254 |

4-φ19 |

4450 |

|

DG14-12G |

2096 |

1207 |

851 |

749 |

749 |

502 |

876 |

152 |

424 |

787 |

610 |

851 |

121 |

4-φ41 |

495 |

552 |

8-φ19 |

210 |

254 |

4-φ19 |

5400 |

|

DG18-16G |

2111 |

1207 |

851 |

749 |

749 |

508 |

876 |

152 |

432 |

914 |

692 |

851 |

-73 |

4-φ41 |

641 |

705 |

8-φ19 |

210 |

254 |

4-φ19 |

6950 |

|

DG18-16TU |

2607 |

1397 |

1194 |

921 |

921 |

703 |

1124 |

222 |

432 |

914 |

692 |

1067 |

143 |

4-φ67 |

641 |

705 |

8-φ19 |

210 |

254 |

4-φ19 |

8850 |

|

DGH10-8S |

1774 |

920 |

760 |

640 |

640 |

455 |

780 |

90 |

330 |

620 |

473 |

450 |

-206 |

4-φ35 |

406 |

457 |

8-φ19 |

210 |

254 |

4-φ19 |

3188 |

Application of Sand Gravel Pump

The Sand Gravel Pump is a versatile pumping solution that finds numerous applications across various industries.

►Mining: The Sand Gravel Pump is widely used in the mining industry to transport abrasive slurries and mining tailings. It is also used for dewatering and transporting minerals like coal, iron ore, copper, and gold.

►Construction: The Sand Gravel Pump is used in construction sites to transfer sand, gravel, and other construction materials from one location to another. It is also used to dewater foundation pits and excavations.

►Dredging: The Sand Gravel Pump is extensively used in the dredging industry to pump sand and gravel from rivers, lakes, and other bodies of water. It is also used in land reclamation projects to pump sand from offshore to onshore locations.

►Agriculture: The Sand Gravel Pump is used in agriculture to pump water and fertilizer from one location to another. It is also used for irrigation and drainage purposes.

►Oil and Gas: The Sand Gravel Pump is used in the oil and gas industry to transport drilling mud and other fluids used in the drilling process.

►Power generation: The Sand Gravel Pump is used in power generation plants to pump fly ash and bottom ash from boilers to ash ponds or ash handling systems.

The Sand Gravel Pump is an essential pumping solution for applications that require the transfer of abrasive and corrosive materials over long distances. Its versatility and reliability make it a valuable asset in various industries.

Sand Gravel Pump Supplier China-DeShi Pump

DeShi is your premier supplier of Sand Gravel Pump solutions in China. Our Sand Gravel Pump range is designed to deliver superior performance and reliability in handling abrasive and corrosive materials, making it the ideal choice for a wide range of industrial applications.

Whether you're looking to move sand and gravel from one location to another or need a reliable pump for your dredging or construction project, the Sand Gravel Pump is a perfect choice. So why wait? Order yours today and experience the power and performance of this exceptional pump!